Shenzhen Kunyo can provide customers with high-quality custom transformers and inductors. Because we have experienced R&D and production teams, and we are familiar with the types and manufacturing requirements of high-frequency materials, and familiar with various high-frequency circuit designs.

This enables us to quickly understand customer design needs. In addition, we have advanced production equipment, allowing us to strictly control product quality and ensure on-time delivery. As we are a direct factory, we can guarantee reliable lead times.

Our magnetic custom components are reasonably priced, with ample stock of conventional materials and fast production speed. We can support small-batch customization. Inquiries are welcome.

A custom transformer is uniquely designed according to the customer’s size, installation, electrical performance, and application environment requirements. It provides customers with more efficient solutions than standard transformers, offering more precise current, voltage, and other parameters to ensure reliability and efficiency.

In practical circuit design, each engineer has different experiences and insights, so custom transformers are designed and produced according to user requirements. This approach satisfies the user’s specific needs, rather than being based on standard models. Custom transformers can more accurately fit into circuits and solve complex input/output requirements, as well as issues related to operating frequency and impedance.

A custom transformer differs from standard transformers as it can be designed according to the customer’s specific application needs and environment. This allows for more precise current and voltage parameters, ensuring greater reliability and efficiency.

Standard transformers may not meet customer needs, such as unsuitable sizes, unacceptable performance, or excessive heat.

Several factors are considered when designing a custom transformer, such as power requirements, PCB space constraints, environmental temperature, size, installation requirements (e.g., connectors, leads, and terminals).

In order to meet the needs of customers, we have a strict process in the process of helping customers customize transformers.

Gather details about the usage scenario, environment, circuit parameters, etc., to fully understand the specifications needed for the custom transformer.

After understanding the customer’s needs, we will provide an appropriate design solution, perform calculations, and run simulations to ensure the reliability and efficiency of the custom transformer.

We will create prototypes based on the design and produce a process guide for manufacturing the custom transformer sample

Customers will test the function and PCB compatibility of the custom transformer samples. If it doesn’t meet the requirements, the design will be revised and new prototypes created.

Once the custom transformer design is confirmed, the customer will sign off on the specifications, and mass production will begin.

Before shipping, we conduct thorough inspections to ensure the custom transformer meets the necessary standards

Before customizing a transformer, confirm all technical parameters to ensure cost control and maximize cost-effectiveness.

Make sure to clearly define your actual needs and budget limits to avoid unnecessary economic losses caused by inaccurate designs or overly complex parameters.

Custom transformers require high-quality materials and advanced manufacturing equipment to ensure that the final product is durable, reliable, and meets quality standards.

We provide custom transformers for a wide range of industries , including audio, medical, industrial, power, and signal applications, etc. During these years, we have established lots of customers in the following industries with our custom transformer.

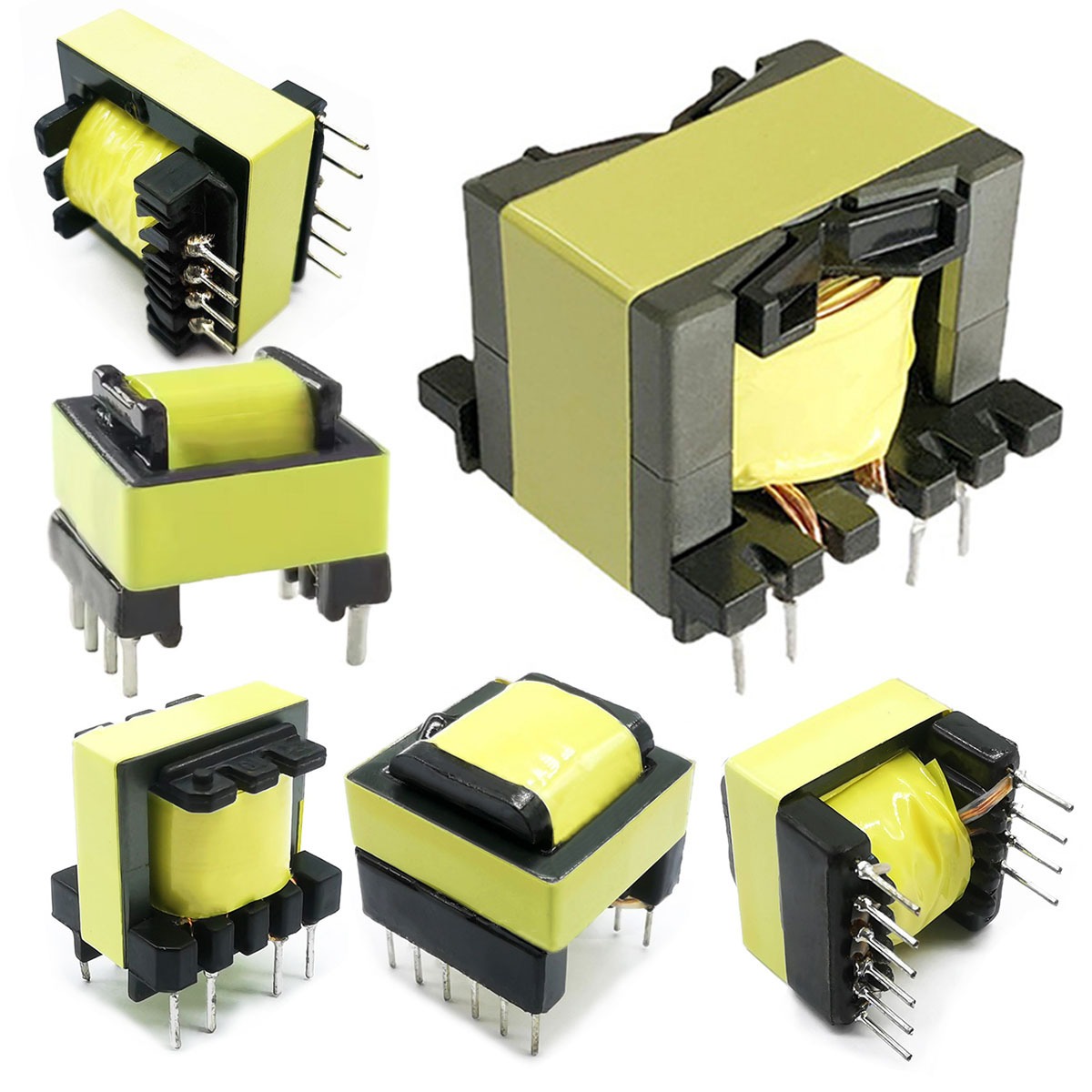

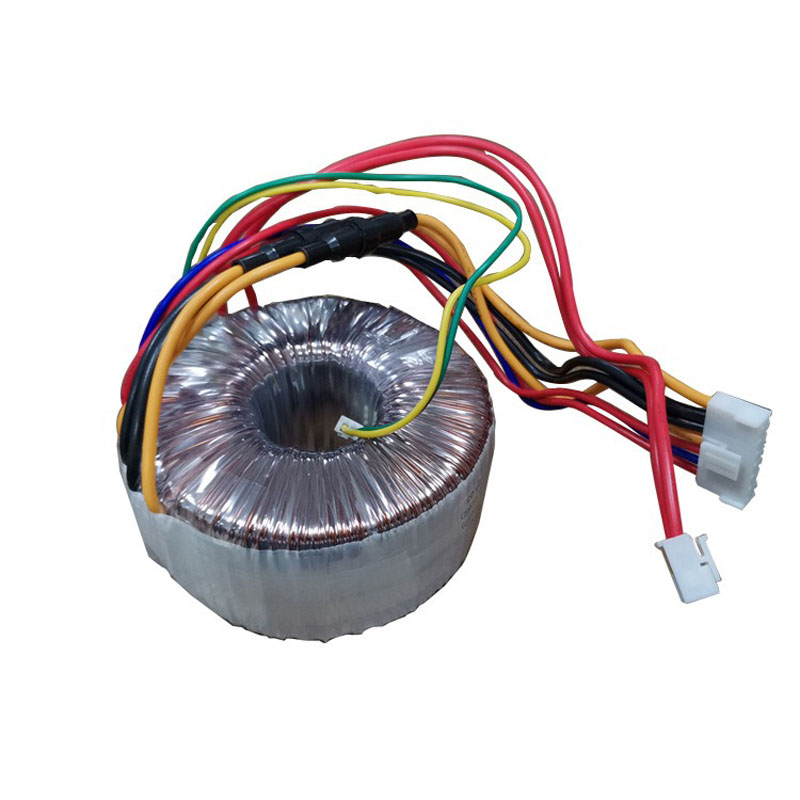

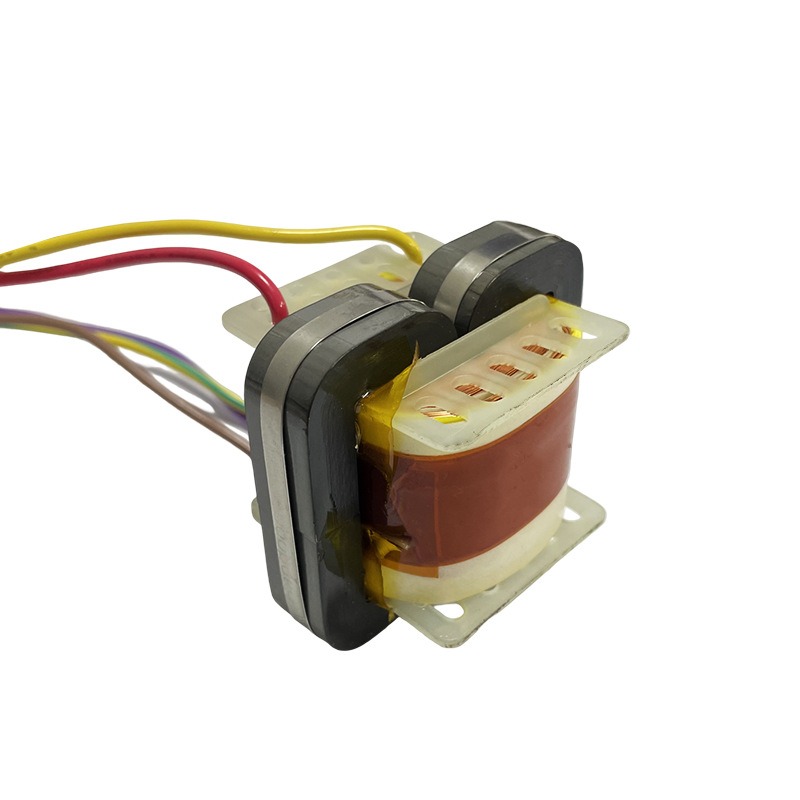

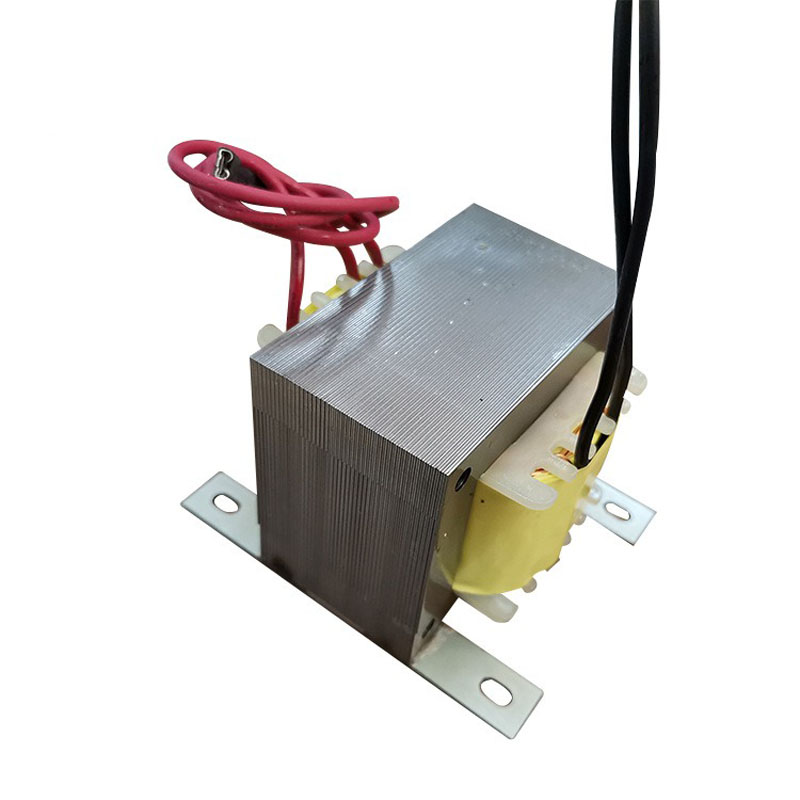

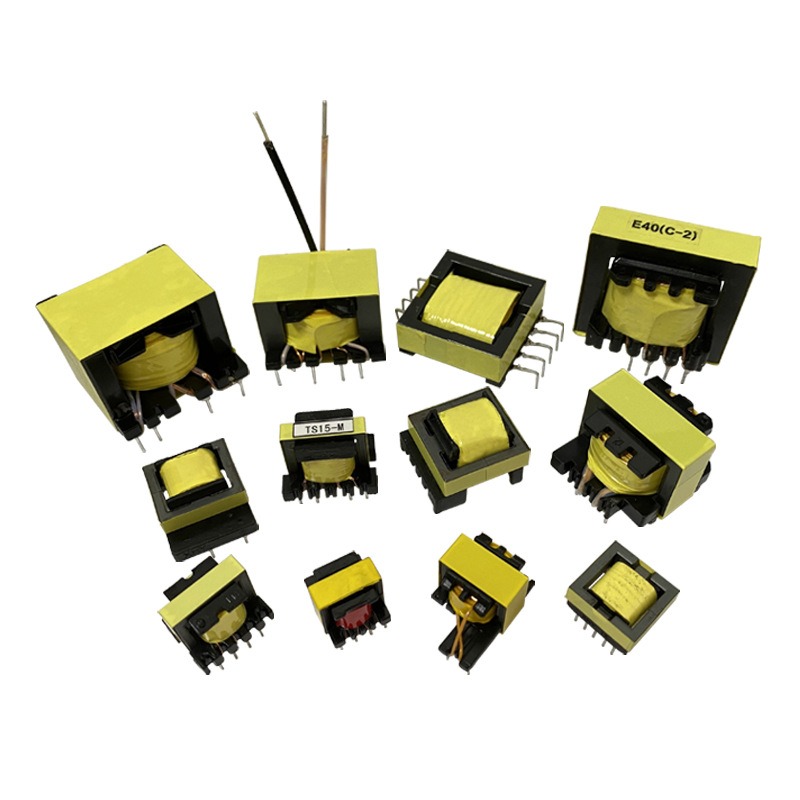

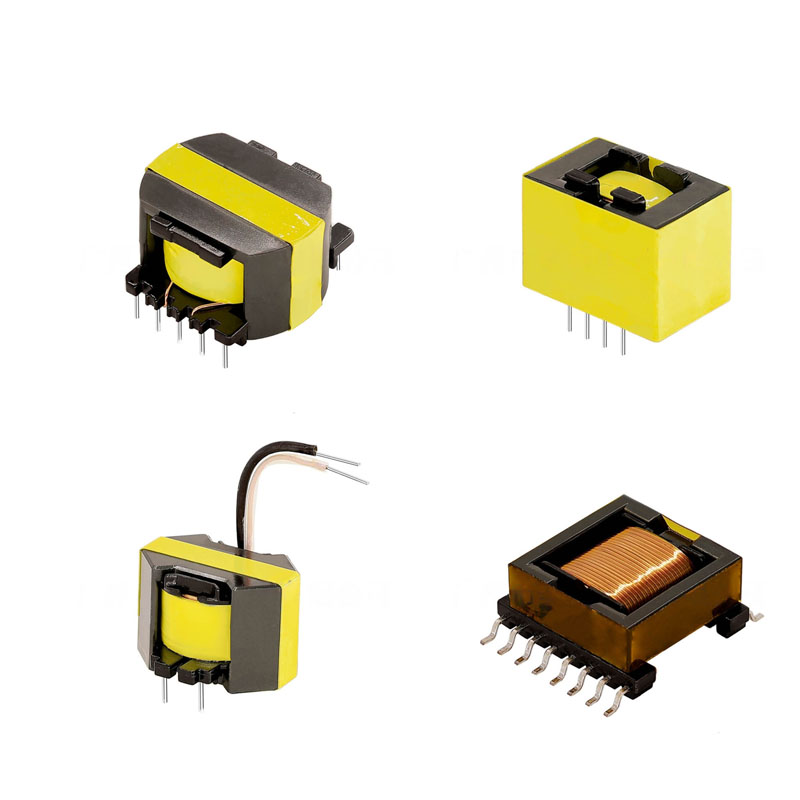

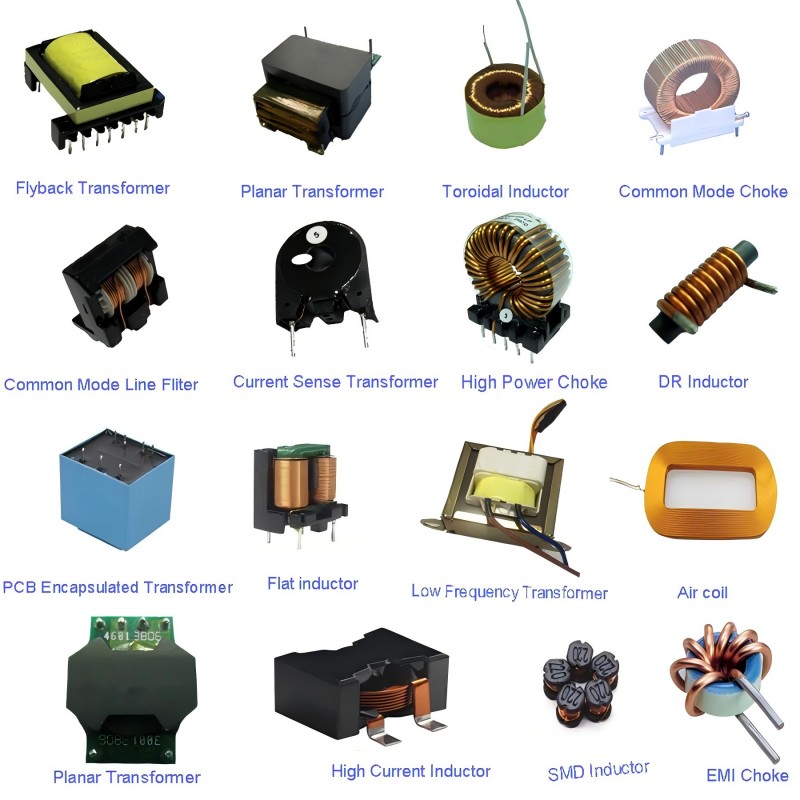

Below are some examples of custom transformers we build:

A custom transformer is an electronic transformer that uses electronic components and circuits to transmit and convert electrical energy. It offers higher frequency response and smaller size.

Custom transformers are used in communication equipment to transform and transmit electrical energy. For example, in fiber optic communication systems, electronic transformers convert electrical energy to optical energy, enabling signal transmission and reception.

Custom transformers play a critical role in power supply systems. They convert electrical energy from the grid into voltage and current suitable for electronic devices. Since different working environments require different transformers, custom transformers provide stable DC power for computers, phones, and other electronic devices.

Custom transformers are widely used in industrial control systems to drive various motors and achieve variable frequency speed control.

Custom transformers are increasingly important in solar and wind energy systems. They convert renewable energy into electrical energy suitable for power systems, facilitating energy storage and distribution.

In automotive electronic systems, custom transformers convert energy from car batteries into suitable voltage and current for vehicle electronic devices. They can also control battery charging and discharging.

Here are some of the custom transformers we produce for our customers:

• Linear Single Phase transformer

• Isolation custom transformer

• Switchmode power transformer

• Step Up transformer

• Step Down transformer

• High frequency custom transformer

• Printed Circuit Mount transformer (Through-Hole transformer,Surface Mount transformer)

• Chassis Mount transformer

• Open Frame transformer

• Shielded custom transformer

• Encapsulated transformer

• Medical transformer

• Ferrite core transformer

If you buy a standard custom transformer, you must confirm the ratings and electrical parameters beforehand to ensure they meet your needs. However, at Shenzhen Kunyo, we can tailor a design solution specifically for your project. We also offer free samples for you to test. Once the samples pass testing and verification, we proceed to mass production.

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.