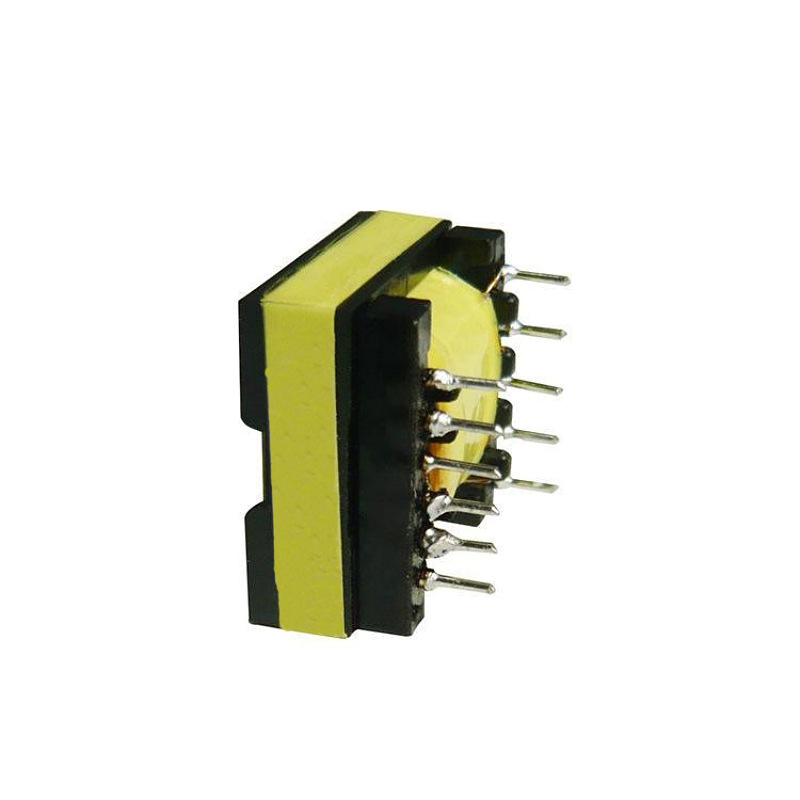

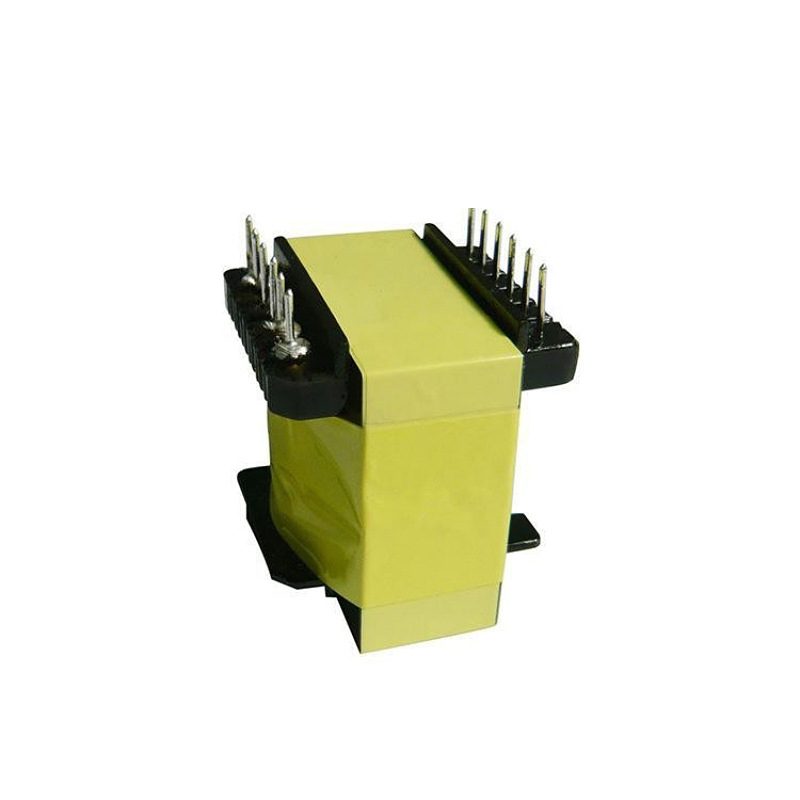

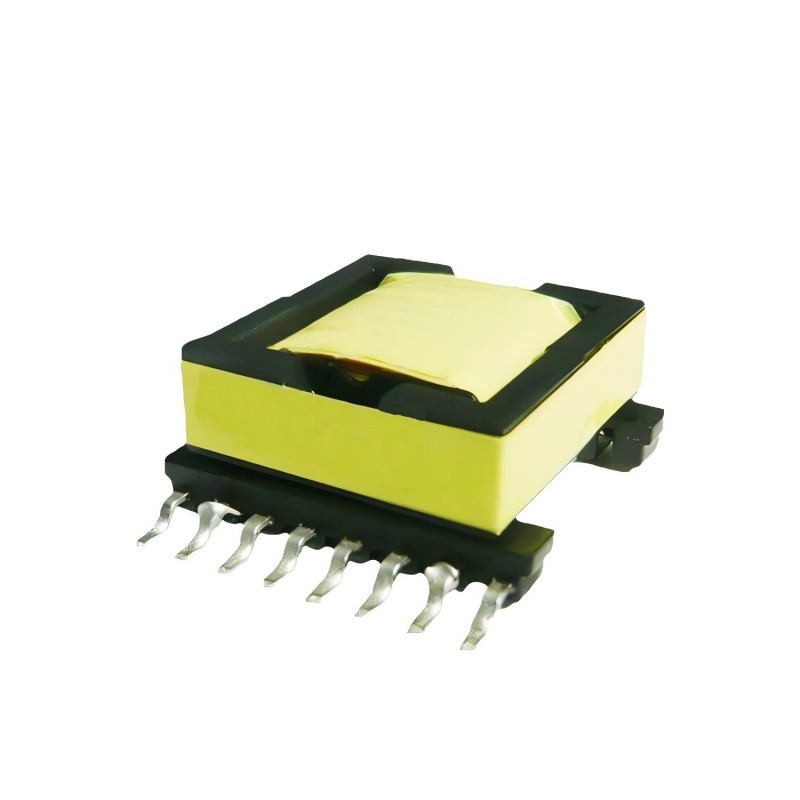

High frequency transformer is a transformer that acts as a transducer and mainly works at high frequencies.

Compared with low frequency transformers, the main difference is that its operating frequency is different. Because the power of the magnetic field is very high, there will be some differences in the selection of materials.

Generally, high frequency ferrite is used as the magnetic ferrite core. However, the working principle of low frequency transformers and high frequency transformers is to transmit energy through electromagnetic induction.

High frequency transformers are small in size and can work at high frequencies. High frequency transformers have a wide range of applications, such as communications, computers, medical treatment, industrial control, aerospace, automobiles and other fields.

A high frequency transformer is a transformer with a working frequency higher than the standard working frequency (50/60Hz). A high frequency transformer is a static electrical device that mainly transmits electrical energy between two or more circuits through electromagnetic induction.

High frequency transformers are mainly used in high frequency switching power supplies, high frequency inverter power supplies and high frequency inverter welding machines,etc.

According to the working frequency, the working frequency range is from several thousand hertz to megahertz. High frequency transformers have the following grades: 10kHz-50kHz, 50kHz-100kHz, 100kHz~500kHz, 500kHz~1MHz, and above 10MHz.

Because high frequency transformers work at high frequencies, more factors need to be considered during design, such as solving problems of proximity effect and leakage inductance/capacitance. Therefore, ferrite cores are always used in high frequency transformers generally.

High Frequency transformers offer many advantages, such as:highly customizable by application, Smaller design requires less materials, high power density. However, when we design the high frequency transformer, we need to consider its design principles in order to meet customers’ requirement.

The leakage inductance of a high-frequency transformer is caused by the incomplete coupling of the magnetic flux between the primary winding and the secondary winding. The magnetic lines of force generated by the coil cannot all pass through the secondary coil, so the inductance that generates leakage magnetic flux is called leakage inductanc

The capacitance formed between the coils of the transformer winding, between the upper and lower layers of the same winding, or between different windings, and between the winding and the shielding layer is called distributed capacitance.

When we design a high-frequency transformer, we usually put the primary winding in the innermost part, because this can make the wire length of each turn of the primary winding the shortest, effectively reducing the distributed capacitance

In the design of a high-frequency transformer, we usually add two or three layers of insulating tape between the primary winding and the secondary winding, so that the capacitance of the distributed capacitance between the primary winding and the secondary winding can be reduced, and the insulation strength between the primary and secondary windings can also be increased.

In order to effectively solve the interference problem of the transformer, in the design of a high-frequency transformer, we usually add copper foil between the windings or the outermost layer of the magnetic core to increase the shielding effect.

During the design of high frequency transformers, insulation and withstand voltage are key point. If the product has high withstand voltage requirements, or the designed safety distance is not enough, we can increase the withstand voltage or safety distance between the primary and secondary by using retaining walls, tapes, sleeves and impregnation processes.

Before shipment, we will conduct 100% testing on each high-frequency transformer product and attach a test report with the goods for traceability.

We are ISO9001 certified, ensuring the highest quality in the industry.

Our high voltage and high frequency transformers can be manufactured in accordance with UL, CUL, VDE and CE standards.

A high-frequency transformer refers to a transformer that works at a high frequency and acts as an energy converter. Because the frequency of the magnetic field is very high, eddy currents will be generated in the silicon steel sheet (the small magnets in the silicon steel sheet cannot keep up with the conversion speed), so high-frequency transformers generally use “high-frequency ferrite” as the core. The difference between high-frequency transformers and low-frequency transformers lies in the difference in their operating frequencies, which leads to some differences in material selection. The working principle of low-frequency transformers and high-frequency transformers is the same. Regardless of the working frequency, energy is transmitted through electromagnetic induction.

Due to the different frequencies of high and low frequencies, high frequencies can only be used in circuits with high frequencies and the excitation source frequency matches the transformer frequency, while low frequencies are the opposite and cannot be mixed. Even if the high frequency does not match the frequency, it is generally not used.

If the transformer transmits a certain amount of energy, the operating frequency is high, the number of energy transmission times within a certain period of time is large, and the energy transmitted each time can be small, then the transformer uses less material and has a small structural size. Therefore, the general high-frequency transformer has fewer coil turns and can be made very small in size, while the low-frequency transformer has more coil turns.

High-frequency transformers with the small size characteristics, can be applied in a wide range of large or small applications.

Consumer electronics

Household appliances

switching power supplies

electric smart meters

Medical equipment

Renewable energy (solar inverters)

Robotics

Motor driversOzone equipment

Battery chargers

UPS

Railway

Established in 2013, Shenzhen Kunyo Technology is committed to designing and manufacturing custom magnetic components, including high-frequency transformers, low-frequency transformers, audio transformers, power transformers, and inductors.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.